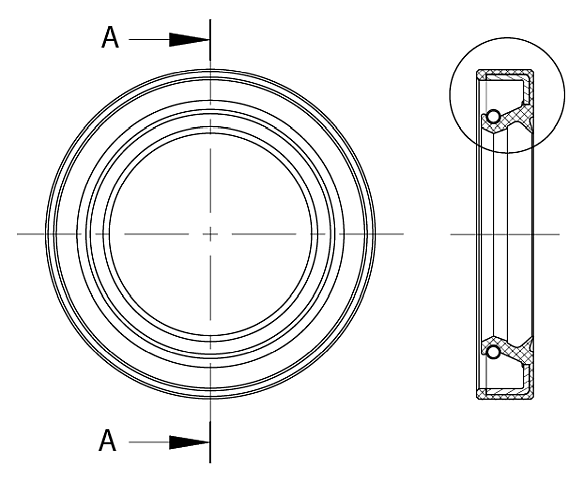

Dimensioning

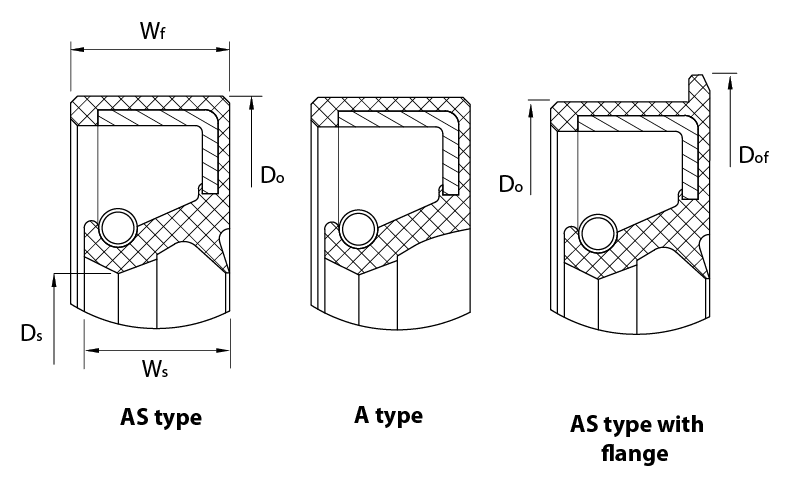

KTT oil seal with rubber housing DIN 3760 A - without dust lip and AS - with dust lip

Typical dimensions:

Ds = shaft diameter (nominal inner diameter)

Do = outer diameter

Dof = outer diameter of flange

Wf = press fit width

Ws = width on shaft surface

Rule of dimensioning: Ds x Do x Wf (default case)

Rules of dimensioning in special cases:- Ds x Do x Wf / Ws: in the case of pressure-resistant type oil seals (BABSL), it is important that the width on the shaft side (Ws) is as small as possible, that's why it is marked separately.

- Ds x Do / Dof x Wf: in the case of oil seals with flange, when a flange extends beyond the external diameter what is important for fitting, the flange outer diameter (Dof) is indicated. The product range of KTT Sealing Technologies includes some oil seals with flange what produced for special needs.

Abbreviations:

AS = radial shaft seals with rubber housing and dust protection lip according to standards DIN 3760 and DIN 3761.

A = radial shaft seals with rubber housing without dust protection lip according to standards DIN 3760 and DIN 3761.

The main production profile of KTT is the manufacturing of A - oil seals without dust protection lip and AS - oil seals with dust protection lip with metal reinforced rubber housing design according to standard DIN 3760 and DIN 3761.

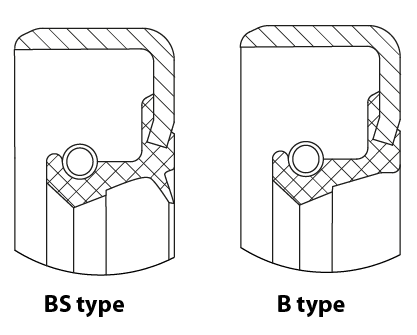

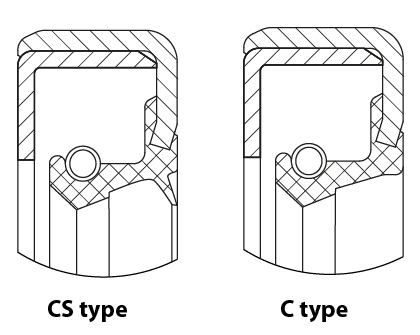

Other common radial shaft seals types

Abbreviations:

BS = radial shaft seals with metal housing and dust protection lip according to standard DIN 3761

B = radial shaft seals with metal housing without dust protection lip according to standard DIN 3761

CS = radial shaft seals with closed metal housing and dust protection lip according to standard DIN 3761

C = radial shaft seals with closed metal housing without dust protection lip according to standard DIN 3761

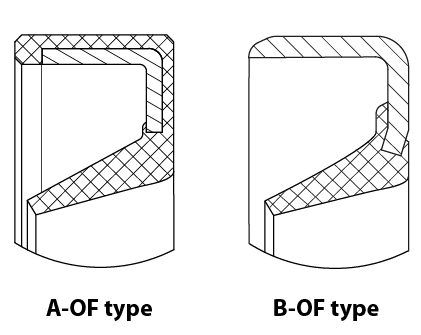

A-OF = radial shaft seals with rubber housing without spring and dust protection lip

B-OF = radial shaft seals with metal housing without spring and dust protection lip

Additional properties

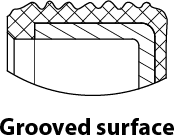

Housing with grooved outer surface

In the case of rubber housing oil seals, in addition to the smooth outer surface, manufacturers often use a grooved outer surface, which helps with more flexible fixation during installation.

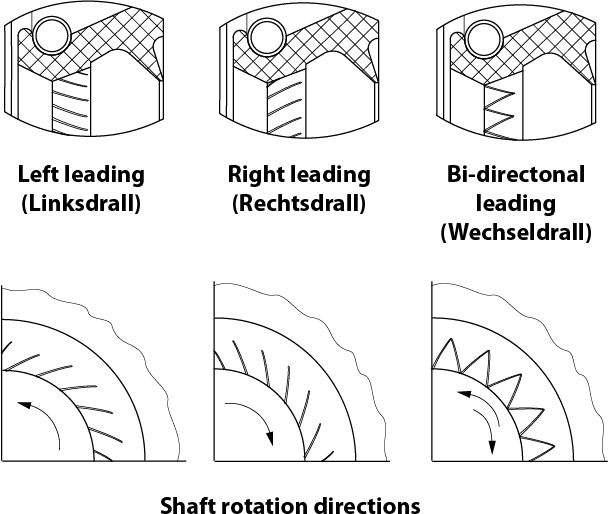

Radial shaft seals with oil leading chanel (drall)

Radial shaft seals that are equipped with an oil return channel are called Left or Right leading type oil seals and also called as "drall" from Germanian naming. There are small notches on the back surface of the sealing lip, which pump the oil from the surface of the rotating shaft back to the inner side of the sealing edge during rotation. It is very important that this kind of special radial shaft seals is selected according to the direction of rotation of the shaft.

Technical guides

- Technical datasheet for KTT oil seals

- Guidance for dimension and material selection based on peripheral speed, rotation speed and shaft diameter

- Material selection guide

- Introduction of elastomers

- Manufacturer's marking system for radial shaft seal types

Application area

Radial shaft seals, also known as simering or oil seals, are used in areas where perfect insulation and protection between the rotating shaft in oily or greasy environment and the outside world is an important aspect. These seals are essentials in preventing the leakage of fluids, oils and other substances while still allowing the shaft to move.

In addition to the traditional radial shaft seals made of NBR material, KTT Sealing Tecnology also produces oil seals made of FKM (FPM, Viton), HNBR, EPDM, silicone (MVQ, VMQ). Moreover we are also able to serve our customers based on individual needs.

When choosing oil seals, an important aspect is the right material to select for the given operating medium, temperature, oil pressure and peripheral speed of the shaft. For high-speed applications the silicone (VMQ) or Viton (FKM, FPM) materials are recommended.

Some typical areas of use:

Automotive

Radial shaft seals are used in engines, transmissions and wheel axles to prevent oil leakage.

Mechanical Industry

These seals are used in many parts of industrial machines and equipment, for example in the shafts of pumps, compressors and rotating machines.

Food Industry

In the food industry, especially in machines where hygiene and a clean environment are important, radial shaft seals are used, for example, in the shafts of mixers and packaging machines. The FDA means in product name the fulfillment for regulation of Food and Drug Administration and this products are surely applicable in food industry.

Proper selection and maintenance of oil seals is key to ensuring efficient and reliable operation of machines.